PermaStruct® design and supply a freestanding handrail to provide safety near rail culverts.

One of Australia’s largest mining companies approached PermaStruct® with a particularly challenging project. “We need a freestanding handrail to provide safety near rail culverts, which complies with Australian Standards. We cannot penetrate the ground to install, it needs to be able to be installed by 1 man and it needs to last a lifetime.”

Typically culverts are unguarded. Concrete is costly and slow to install, while the steel will rust and gradually disintegrate.

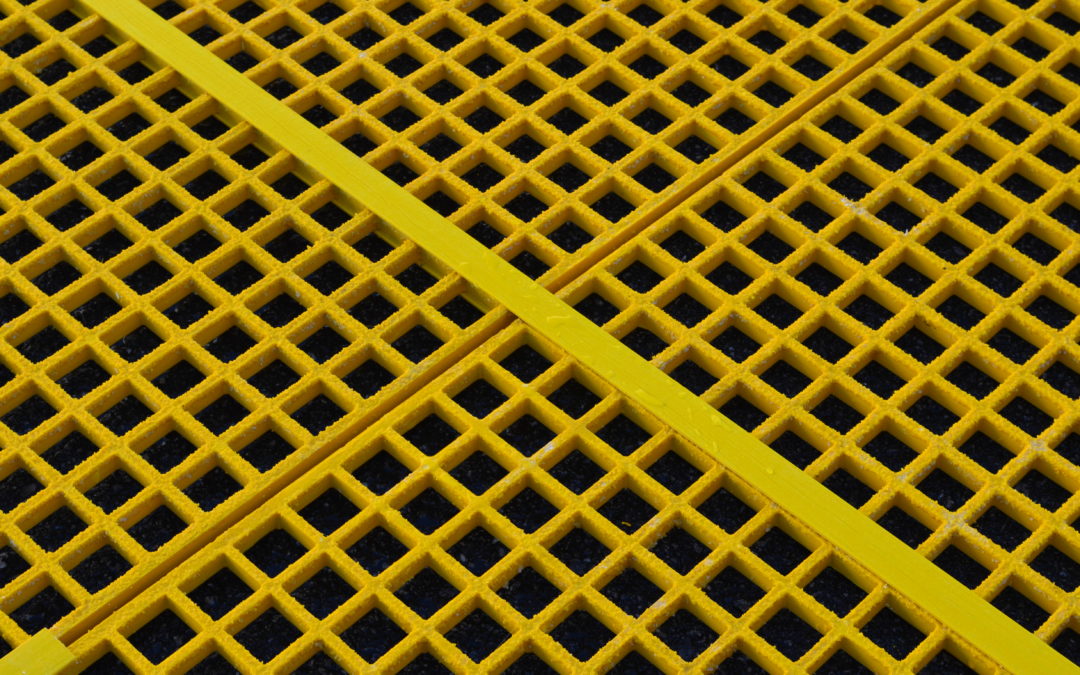

Together with the client, PermaStruct® developed an FRP modular, freestanding handrail system that met all of the requirements of the project. Australian Standards are complied with via the counterweights, providing more than enough support to meet the load requirements of a ‘fixed in’ handrail system. It can be easily installed by a single operator, as all of the sections fall under 15kgs each (the one man lift limit) and it will last a lifetime as its made entirely from PermaStruct® FRP.

The platforms require zero ongoing maintenance, the modules can be moved around the site, reused, joined in a matter of minutes and the need for large and expensive installation teams is unnecessary; reducing the installation and maintenance costs.

The PermaStruct® Freestanding Handrail is flexible in design and can be used in lengths from 10 metres to 1000m, maintaining the same standards of safety, aesthetics and longevity.

Learn more about PermaStruct® Handrail systems here.